The Victron Smart Shunt is an advanced device used for monitoring battery systems in marine, automotive, and off-grid applications. It allows users to accurately track battery voltage, current, and state of charge while communicating with other Victron devices via Bluetooth or VE.Direct. Understanding the Victron Smart Shunt wiring diagram is essential for proper installation, ensuring accurate data collection, and preventing potential damage to the battery system. A correct wiring setup not only enhances monitoring accuracy but also allows for integration with Victron’s ecosystem, including the VictronConnect app, solar chargers, and inverters. This topic explores the components, wiring process, and practical applications of the Victron Smart Shunt in modern battery management systems.

Overview of Victron Smart Shunt

The Victron Smart Shunt functions as a digital current sensor and battery monitor, designed to provide detailed real-time information about your battery system. Unlike traditional shunts that only measure current, the Smart Shunt can transmit data wirelessly to compatible devices, giving users instant access to voltage, current, and amp-hour usage. It is suitable for lithium and lead-acid battery types and can be installed in boats, RVs, solar setups, and off-grid homes. Its compact design allows for easy integration, and the inclusion of Bluetooth connectivity enables wireless monitoring without additional displays.

Components of the Smart Shunt System

- Smart Shunt UnitThe main device containing the current-sensing shunt and electronics for monitoring and communication.

- Battery ConnectionsTerminals for positive and negative battery connections to measure current flow accurately.

- Load ConnectionsTerminals connecting to the main load to track current consumption.

- Bluetooth or VE.Direct InterfaceEnables wireless communication with VictronConnect or integration with Victron products like GX devices.

- Optional Remote Monitoring DevicesSuch as the BMV series displays, which can be connected to provide additional readouts of battery status.

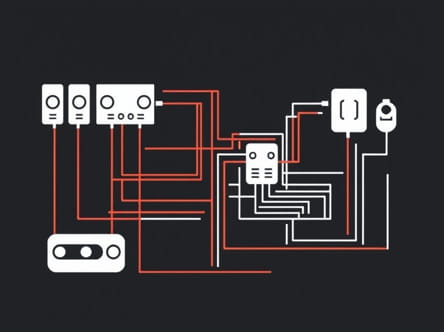

Understanding the Victron Smart Shunt Wiring Diagram

The Victron Smart Shunt wiring diagram provides a clear map of how to connect the device to a battery and its load. The diagram typically illustrates connections for the battery negative terminal, load negative terminal, and any auxiliary devices. Correct placement of the shunt in the negative line of the battery ensures that all current entering or leaving the battery is measured accurately. Positive connections usually bypass the shunt, connecting directly to the battery positive terminal. Understanding each terminal and wire in the diagram is crucial to avoid installation errors that could result in incorrect readings or potential damage to the shunt and battery system.

Step-by-Step Wiring Guide

Following the wiring diagram, the installation process of the Victron Smart Shunt involves several key steps

- Identify the negative terminal of the battery where the shunt will be connected.

- Connect the main negative battery cable to the Battery terminal on the shunt.

- Connect the load or inverter negative cable to the Load terminal on the shunt, ensuring all current leaving the battery passes through the shunt.

- Verify that the positive battery connections bypass the shunt and go directly to the load or system bus.

- Power on the system and pair the Smart Shunt with the VictronConnect app via Bluetooth or connect through VE.Direct for monitoring.

- Confirm proper operation by checking voltage, current, and amp-hour readings in the app or on connected display devices.

Integration with Victron Ecosystem

The Smart Shunt can be integrated with other Victron products for enhanced battery management. For example, connecting it to a Victron GX device allows centralized monitoring of solar chargers, inverters, and battery systems. The device can also communicate with the VictronConnect app to provide alerts, logs, and historical data for better decision-making. Proper wiring ensures that all connected devices receive accurate information, allowing users to optimize battery usage, prevent overcharging or deep discharging, and extend the lifespan of their battery systems.

Common Applications

The Victron Smart Shunt is suitable for a variety of applications, particularly where accurate battery monitoring is essential. Some common use cases include

- Marine SystemsMonitoring batteries on boats and yachts for navigation, lighting, and onboard electronics.

- Recreational Vehicles (RVs)Managing battery banks for lighting, refrigeration, and other onboard systems.

- Solar InstallationsTracking energy storage and consumption in off-grid solar setups.

- Off-Grid HomesProviding real-time data for battery health and energy usage in remote power systems.

- Industrial EquipmentEnsuring reliable power management for backup batteries in critical systems.

Safety and Best Practices

When wiring the Victron Smart Shunt, safety should be a top priority. Always ensure the battery system is disconnected before making any connections to prevent electric shock or short circuits. Use proper gauge wires and secure connections to minimize resistance and avoid overheating. Verify that the shunt is installed in the negative line as indicated in the wiring diagram, since incorrect placement can result in inaccurate readings. Additionally, avoid exposing the shunt to moisture or extreme temperatures to maintain reliable operation. Following these best practices helps protect both the device and the battery system.

Advantages of Proper Wiring

- Accurate measurement of battery voltage, current, and state of charge.

- Reliable wireless monitoring via VictronConnect or VE.Direct integration.

- Enhanced battery management and extended lifespan of battery systems.

- Compatibility with a range of Victron products for centralized monitoring.

- Reduced risk of misreading or system errors due to improper installation.

Troubleshooting and Maintenance

Even with a clear wiring diagram, issues can occur during installation or operation. Common problems include incorrect readings, failure to connect to the app, or unstable measurements. Troubleshooting steps include verifying all connections according to the wiring diagram, checking wire gauge and tightness, and ensuring the device firmware is up to date. Regular maintenance, such as cleaning terminals and inspecting for corrosion or damage, ensures continued accurate performance. Using the VictronConnect app to check live data and logs can help identify anomalies and allow for prompt corrective action.

The Victron Smart Shunt wiring diagram is an essential reference for anyone looking to implement advanced battery monitoring in marine, RV, solar, or industrial systems. Proper understanding and application of the diagram ensure accurate current, voltage, and state-of-charge measurements while allowing seamless integration with Victron products. By following recommended installation steps, maintaining connections, and integrating the shunt with monitoring tools, users can optimize battery performance, enhance system efficiency, and prolong the life of their energy storage solutions. The Smart Shunt remains a versatile and indispensable component in modern energy management systems, providing both real-time data and long-term insights into battery usage.